Parker processing job

Automotive parts

It is used in products that require high functions such as corrosion resistance and sliding performance and long warranty.

Overview

Many parts of automobiles are required to have high corrosion resistance and sliding properties. Parker processing We will propose a variety of surface treatments to match the products required.

Corresponding processing

Paprobond

Products, parts, etc. that are relatively inexpensive, have corrosion resistance, paint adhesion, and require rust prevention performance It is used.

Click here for detailsPAPRO SLIDE M

With superior performance in corrosion resistance, sliding, noise reduction, pitching and scoring

Click here for detailsPAPRO SLIDE

Gears and cams that require high sliding performance that are impossible to accommodate with the PAPRO SLIDE M.Used in parts such as shafts and pistons.

Click here for detailsPAPRO SLIDE SP

Differential part used in high load range which can not be handled even by a PAPRO SLIDE.It is used in parts groups, etc.

Click here for detailsPAPRO Forg

Phosphate treatment + metal soap increases cold forgeability.Inexpensive lubrication treatment Used as a seat spring, etc.

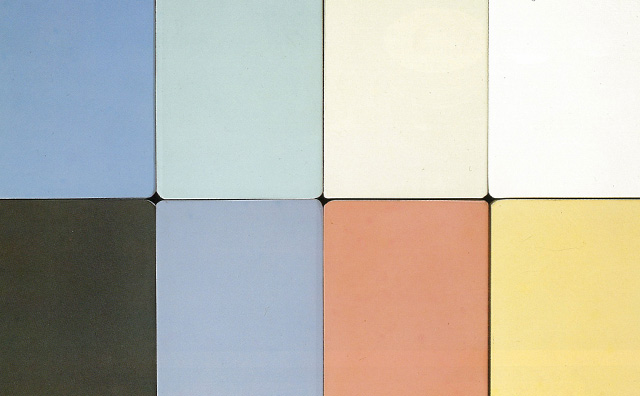

Click here for detailsBuilding materials, interior and exterior

Improve rust prevention, aesthetics, and design of steel panels, galvanized building materials, etc.

Overview

Steel panels are susceptible to rust as they are and require surface treatment for aesthetics. In addition, galvanized building materials are often said to have a metallic luster when used as they are, which impairs the surrounding landscape.

Corresponding processing

PAPRO Harmony

Zinc-plated surfaces are coated with phosphate coating to improve design performance with corrosion resistance and a comfortable color tone.

Click here for detailsPAPRO Coat

High rust prevention performance and durability can be obtained by painting after surface treatment according to the material of the building material.

Click here for detailsHome appliance parts

We can propose a surface treatment that makes it easier for electricity to pass through or to pass through easily.

Overview

Home appliances are made of a wide variety of materials, including metals and resins. However, there are some parts that need to be partially made easy to pass electricity through or pass through.These requirements are solved by the surface treatment of parker processing.

Corresponding processing

PAPRO Slide

We propose optimal surface treatment by combining surface treatment and paint film that match the materials.

Click here for detailsPAPRO Resist

Provides a surface treatment that prevents electricity from passing through parts such as metals.

Click here for detailsPAPRO Elec

Surface treatment is applied to organic resins, glass, and other products that are difficult to pass electricity through.

Click here for detailsPAPRO Fric

Coating film is formed according to the surface and application of the material, and high friction coefficient is given.

Click here for detailsPAPRO Ecoat

Hexavalent chromium-free surface treatment is applied to light metals such as aluminum products to enhance corrosion resistance.

Click here for detailsPAPRO Thermo

Heat resistance is improved by surface treatment of heat-generating parts, etc.

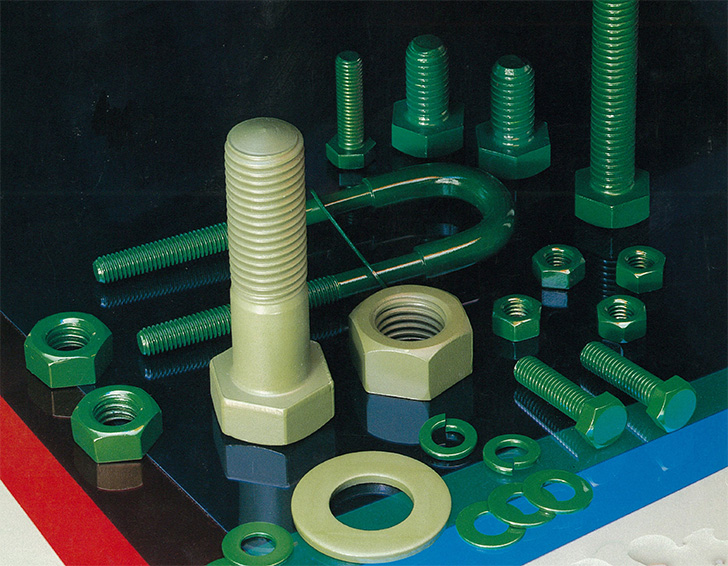

Click here for detailsBolts and other fastening parts

Bolts, fastening parts, bridges, steel towers, and other structures requiring long-term rust prevention, as well as fastening bolts, can be treated for high corrosion resistance and tightening torque stabilization.

Overview

Bridges, steel towers, etc. are exposed to the atmosphere for a long period of time, and high rust prevention is required. You do. In addition, the fastening bolts used in those buildings are required to obtain stable tightening torque values in addition to high corrosion resistance. The surface treatment of parker processing can propose a treatment that meets these high requirements.

Corresponding processing

PAPRO Coat

Painting is performed after surface treatment suitable for the material to obtain weather resistance, rust prevention performance and design properties according to the customer's requirements.

Click here for detailsPAPRO Slide

We propose a highly torque-stable surface treatment by combining a surface treatment suitable for the material with a coating film with a stable friction coefficient value.

Click here for detailsHousehold goods

We propose a surface treatment that makes the design and comfort of products that we directly see and touch with hands comfortable.

Overview

We propose surface treatments that satisfy customer requirements by applying surface treatments and painting that match the materials.

Corresponding processing

PAPRO Coat

By applying surface treatment and painting in accordance with the materials, we propose surface treatment with aesthetics and functions in a wide range of materials.

Click here for detailsPAPRO Un Adhe

We propose a treatment that adds a dirt-resistant function and a water repellent function.

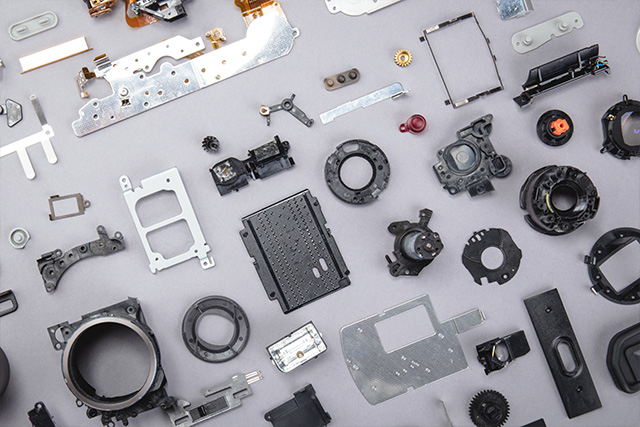

Click here for detailsPrecision/Optical Equipment Components

Controls the movement of the mechanical parts of optical products, such as cameras, and the flow of light.

Overview

Smooths mechanical movements such as shutter, zoom, and aperture of the camera, etc. It also suppresses harmful light flow when taking pictures such as diffuse reflection of light. In addition, we can propose a surface treatment that shields electromagnetic waves that cause malfunctions such as electromagnetic waves.

Corresponding processing

PAPRO Slide

We propose a surface treatment that optimizes the friction resistance value for each part.

Click here for detailsPAPRO Coat

We propose surface treatment and painting with design and texture in line with customer requirements.

Click here for detailsPAPROELEC

We propose a conductive surface treatment that shields harmful electromagnetic waves.

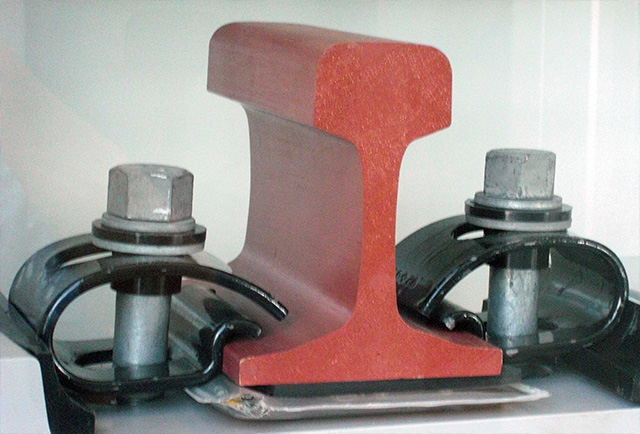

Click here for detailsTransportation & Railway Equipment

We propose optimal surface treatment for parts that require high corrosion resistance and stable sliding properties, such as vehicles, tracks, overhead wires, etc.

Overview

Railway substrates, which require high safety and long durability, need surface treatment that can cope with a wide range of technologies.

Corresponding processing

PAPRO Slide

It is used to prevent displacement caused by expansion and contraction of rails and other fastening parts due to heat.

Click here for detailsPAPRO Coat

Surface treatment with high anti-rust capability and hard hardness enables a wider maintenance interval than before (last stay treatment).

Click here for detailsOther industrial products

Parker-processed surface treatment is used in condominium conduits, seismic isolators, and other locations that are not visible.

Overview

For example, apartment buildings and detached houses are equipped with vibration isolators and vibration control devices that reduce earthquakes and other shaking. These devices also use treatment to improve the sliding and adhesion of parker processing. Parker finishing is also used for parts that are not normally noticed, such as gas appliances, which are rust resistant, heat resistant, and sliding gas plugs.

Corresponding processing

PAPRO Slide

By applying it to the surface of the product, the frictional resistance value can be kept constant and the performance of the vibration isolator, etc., can be stabilized.

Click here for detailsPAPRO Bond

Phosphate treatment is used to improve the adhesive strength between rubber and metal in seismic isolation equipment.

Click here for detailsPAPRO Thermo

It is used to prevent corrosion in the high temperature range of gas cooking stoves such as Gotoku and quartz tube heaters.

Click here for details